Case Study: Ensuring Public Health and Safety

Managing the Cold Room Environment to Maintain Inventory Integrity

CHALLENGES

A government public health agency was experiencing problems with its wired monitoring system’s ability to display temperatures of the cold storage equipment. This included customized distributed enclosures with traditional digital displays on industrial refrigerators/freezers and within cold rooms.

Cold rooms, chill rooms, and freezers need to be monitored closely to avoid equipment malfunctions, which can ruin inventory and lead to additional costs, not to mention the cost of not responding effectively to public health situations. The agency’s system was experiencing inadequate environmental and condition monitoring due to cabling issues, display failure, inaccuracy, and maintainability problems. These issues were causing the system to fail as a result.

In addition, workers had to manage temperature monitoring on some freezers one at a time, which was cumbersome and time consuming. Other freezers were equipped with a legacy system with 20-year-old thermostats that did not have automated temperature monitoring and out-of-range detection capability. This posed a high risk for damage to valuable inventory such as blood and vaccines. To address these challenges, the agency wanted to upgrade its wired monitoring system to a system that is based on wireless and IoT technology. A system that provides monitoring and recording of equipment as well as environmental temperature and humidity, track operational condition of cold room doors open or close status, and personnel safety from man trap in cold rooms. It also required a system that provides cost savings from an installation perspective and cost savings from ongoing operation and maintenance. The system needed to be quick and easy to deploy while providing visibility into all device performance and their effects on the environment. Also, the agency needed to adhere to the regulations surrounding temperature monitoring and accurate record-keeping, a necessity for pharmaceutical storage facilities. To address these challenges, the agency requested assistance from WinSys Technology Pte Ltd to provide a computerized system with a wireless sensor solution. WinSys Technology Pte Ltd, was able to provide a simple, yet robust solution that communicates and visualizes data in industrial applications.

THE SOLUTION

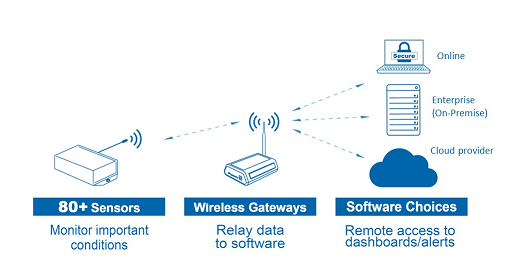

WinSys Technology Pte Ltd recommended an easy-to-use and deploy computerized solution that leveraged on the latest IoT technology. As a total solution provider, WinSys Technology Pte Ltd has a pool of highly skilled and experienced professionals that provides precise and cost-effective solutions to meet its clients’ business needs. As a result, the company managed to offer assessment, design, installation, and maintenance services that are essential to provide the best business outcome for its clients and in turn establish long-term value and business relationships. The agency chose Winsys’ Wireless Monitoring System because it includes tools to visualize, analyze, and with alarm notifications based on its performance requirement and security needs, easing deployment, and allowing immediate use of collected data. Also, the robust IoT sensing technology delivers granular data at a fraction of the time and cost of wired solutions. WinSys Technology Pte Ltd performed the physical installation and configuration of the system, integration into the company’s existing environment monitoring system, and ongoing system maintenance. The Wireless Monitoring System provides the agency a low cost, easy-to-deploy solution to gather, communicate, and visualize data in its cold storage facility to improve reliability, product quality, operational efficiency, and energy optimization. Specifically, the system addressed the agency’s request for wireless IoT temperature and humidity sensors, door open/close sensors, and dry contact sensors, along with sensor gateways and software. Winsys supported the agency in assessing the operational environment and was able to select a product range that is cost effective and adequate for the application.

The Wireless Monitoring System also provides the following capabilities:

• Non-line of sight/indoors for greater penetration through walls, ceilings, and floors to help improve operational efficiency

• Easy mounting options and wireless placement of sensors at any point to avoid the cost and time of installing complex or additional connectivity

• Automatic time stamping for all sensor data indicates and documents the exact time at which an event is collected, allowing historical logs and comparison capability

• Sends messages to confirm the connection between gateway and sensors to ensure data integrity

• Allows interconnect ability of up to 100 sensors on a single wireless network gateway through one single IP address, reducing the need for separate IP ports, IP capital costs, and management overhead

• Helps manage plant operations with graphs, charts, alarms/alerts, and sensor data mapping, reducing plant maintenance time and cost

• Delivers a secure solution for customers to evaluate the system via private enterprise server or in the cloud for flexibility and ease of use • Real-time notification of “out of state” conditions — Single pane of glass monitoring and management — Operational cost reduction — Greater signal propagation for increased distance and increased penetration.

BUSINESS BENEFITS

With the capability to visualize and analyze along with alarm notification system based on customer needs, the Wireless Monitoring System was the right choice for the agency and is vital to its operations. Moving forward, the agency can address connectivity issues more quickly and establish a long-term foundation for increased uptime. Deployment is easy with no cabling needed for sensors and the system allows immediate use of collected data. Therefore, the agency now has the best capability to leverage insights to deliver product quality, operational efficiency, and energy optimization.